Choosing the right drive for tough environments

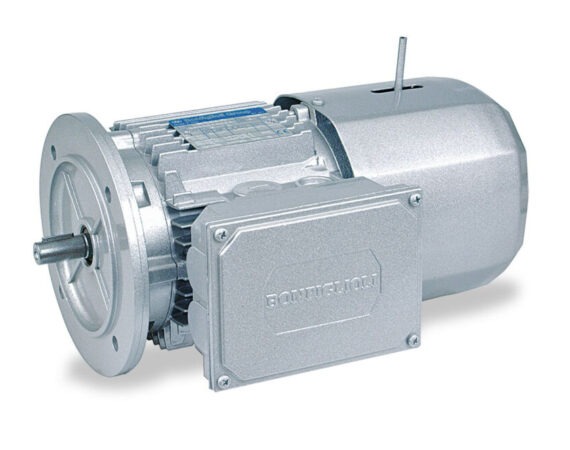

When a project hinges on reliable torque and predictable control, a gearbox motor is more than a box with gears. It blends mechanical strength with a precise speed profile, letting engineers tailor load response to fan housings, conveyors, or mixers. In harsh settings, metal housings, sealed bearings, and oil- lubricant gaps keep grit out and life in. gearbox motor The key is pairing the unit to the task: high reduction gears for slow, torquey starts; compact ratios for snappy cycles; and backlash minimised through careful meshing. This pragmatic mix makes maintenance clearer and downtime shorter, so teams can plan service windows with real confidence rather than guesswork.

Efficiency gains from smart drives in mills

The bonfiglioli vfd is a common sight in modern lines because it turns simple speed control into energy savings. Rather than a blunt on-off, soft starts cut peak currents and reduce wear on belts and couplings. In a mill setting, this means smoother belt tension, less vibration, and a more bonfiglioli vfd stable process window. Integration with a motor-friendly interface helps operators tune torque limits without sparking faults in the control loop. The practical upshot: fewer emergency stops and a cleaner power bill, especially when multiple units run in parallel under variable loads.

Sizing and compatibility across components

Getting the right fit means translating mechanical needs into electrical specs. A careful look at gearing ratio, input speed, and motor envelope avoids a mismatch that would thrash bearings or hum loudly at full load. With a well-chosen setup, the gearbox motor brings predictable inertia, quicker ramping, and a calmer start sequence. Compatibility matters, too, from mounting feet to shaft ends and couplings that dampen misalignment. The goal is a neat, robust chain where each part accepts the others’ rhythms, keeping noise down and performance steady as hours roll by.

Maintenance myths debunked in ageing gear trains

Old myths die hard in maintenance rooms, especially around gearbox life and oil changes. A modern approach treats seals and gears as a system, not a single piece. Regular oil checks with the right specification cut sludge and heat soak, while clean breathers and venting stop pressure build-ups. Audible wear signals like a faint chatter can hint at misalignment long before a failure, letting teams plan a repair. The message is practical: check lubrication, monitor temperature, and verify alignment during every service window to extend the gearbox motor’s service life, not chase vague warnings.

Installation tips for compact setups

In tight spaces, layout decisions shape performance more than any fancy control feature. A compact gearbox motor benefits from short, straight runs of cable to reduce inductive spikes and from a neat chain path that avoids cross-loads. Mounting orientation matters for lubrication return and heat dissipation, so places with good airflow win. Using a proven motor starter or a friendly VFD interface helps avoid surges and balances torque across the drive train. Concrete steps like pre-lubing at install and recording shaft alignment for future checks pay dividends when the line scales up.

Conclusion

In the end, practical choices about drives, gearing, and control add up to fewer faults and steadier outputs. The market offers a spectrum of robust options for the machine floor, from rugged gearbox assemblies to adaptable drive modules, each chosen to match load, speed, and duty cycle. The important thing is a clear plan: know the task, specify the right gear ratios, and confirm the control interface supports the intended sequence. Real reliability comes from steady maintenance, smart monitoring, and a well-structured spare strategy that avoids slowdowns. For teams pursuing sturdy, predictable performance, the latest catalogue of products from everestrkd.com provides a supportive map to the right fit, helping operators avoid overkill while securing long-term confidence in every line.