Innovating with a steady hand

Operating in tight warehouses demands a real partner, and the AMR & AGV supplier landscape offers plans that fit. This sector isn’t just about robots; it’s about the flow of goods and the ease of day-to-day tasks. An AMR & AGV supplier worth listening to maps routes that adapt on the fly, AMR & AGV supplier trims idle trips, and helps staff keep pace without shouting about efficiency. The right approach blends hardware with software, so a fleet can learn from traffic patterns and adjust without fragile tweaks. In practice, those tweaks become stable gains over weeks rather than months.

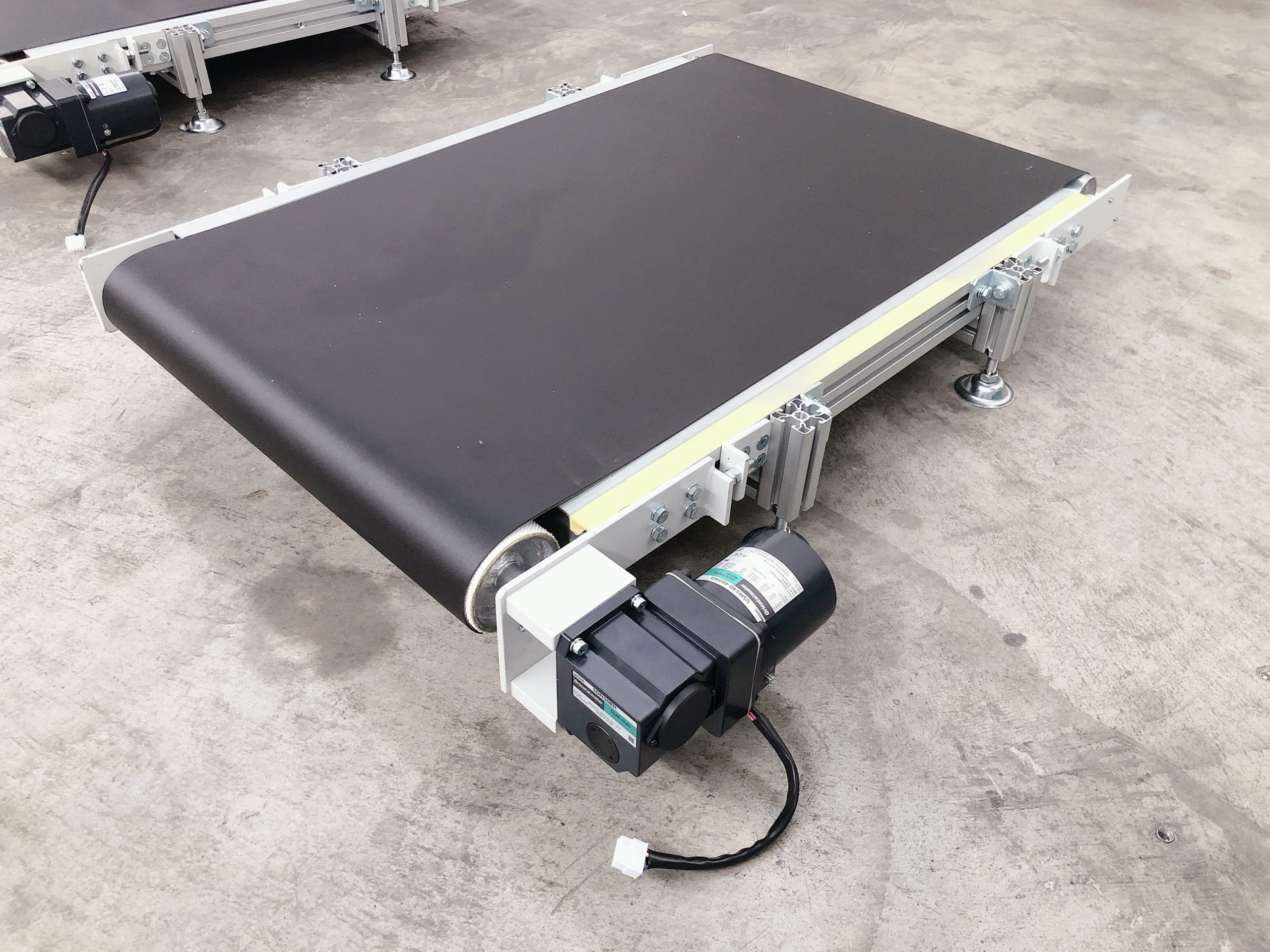

Hardware that fits real spaces

When a site has narrow aisles, slanted floors, and active humans, the AMR & AGV supplier must bring machines that handle such quirks with grace. Small, nimble units can reach high shelves and still glide past people without pauses. It’s not about pushing bigger machines; it’s about smarter machines. A good AMR & AGV supplier tests in similar warehouses, then tunes sensor ranges, bumper zones, and charging cycles so that downtime stays low and predictability rises. Real space constraints become a design brief, not a hurdle.

Software that keeps pace with growth

The best AMR & AGV supplier choices bundle software that respects existing inventory systems while offering a clear upgrade path. Think fleet management dashboards that show live location, load status, and battery health at a glance. The aim is human-readable intel that fits a supervisor’s day rather than a programmer’s week. This software layer should also stage safe interactions with workers, using geofences and slow zones where needed. In practice, that means fewer surprises and smoother handoffs between tasks.

Safety first, every step of the way

Any AMR & AGV supplier worth the label will foreground safety, not elasticity alone. Robots must pause for pedestrians, adjust speed in busy lanes, and alert noisy corners where sight lines are poor. A strong safety plan includes routine checks, spare parts availability, and clear calibration routines. Less downtime comes from a modular approach—quick swaps for wheels, sensors, or drive units—so maintenance doesn’t stall entire shifts. The result is reliable comfort for teams that learn to trust the machines as partners on the floor.

Service that keeps the system singing

Choosing an AMR & AGV supplier means looking for aftercare that sticks. On-site visits, remote diagnostics, and spare parts quick lanes matter most when the fleet expands. A responsive support rhythm reduces the risk of long outages and keeps operations humming. This isn’t just about a one-off sale; it’s about a plan that grows with the business. Real-world trials help prove concepts, while clear SLAs translate into predictable costs and dependable uptime.

Conclusion

From initial assessment to daily routines, the AMR & AGV supplier landscape must support practical, tangible wins. The right partner brings machines that work in real spaces, software that clarifies decisions, and service that resolves issues before they disrupt shifts. Safety isn’t an add-on but a core principle, woven through AMR & AGV supplier every operation and every maintenance check. By prioritising modularity and responsiveness, warehouses see fewer stops, smoother transitions between tasks, and a clearer path to future scale. Brands like sacs.com.my are part of this evolving picture, offering choices that align with real world needs and steady, proven performance in the field.