Precision in the wash: equipment that pays for itself

The heart of any beverage or food line rests on reliable, repeatable cleaning. Industrial can cleaning machinery should stand up to daily cycles, salt spray, and stubborn dried residue without faltering. Operators notice the difference the moment a conveyor slows or a nozzle clogs. A well‑tuned system uses low water volume with high spray pressure, reclaimable industrial can cleaning machinery wash cycles, and smart filtration to cut waste. It’s not just about spotless cans; it’s about predictable throughput, clean-in-place readiness, and minimal downtime for maintenance. When a plant rethinks its wash stage, it often unlocks faster changeovers and sharper product quality with less variance across a shift.

A practical lens on turnkey packaging line solutions

Turnkey packaging line solutions promise a lot, but the real test is how smoothly a line boots up, from pallet to shrink wrap. Key factors include modularity, simple controls, and traceable sanitation records. In practice, a good turnkey setup reduces the number of third-party vendors and shortens the path from order to turnkey packaging line solutions running lines. Operators benefit from clearly labelled panels, intuitive touchscreens, and built‑in fault diagnostics. In a busy plant, this means fewer stalled lines, quicker start‑ups after changeovers, and better alignment with predictive maintenance schedules so every shift starts with confidence rather than speculation.

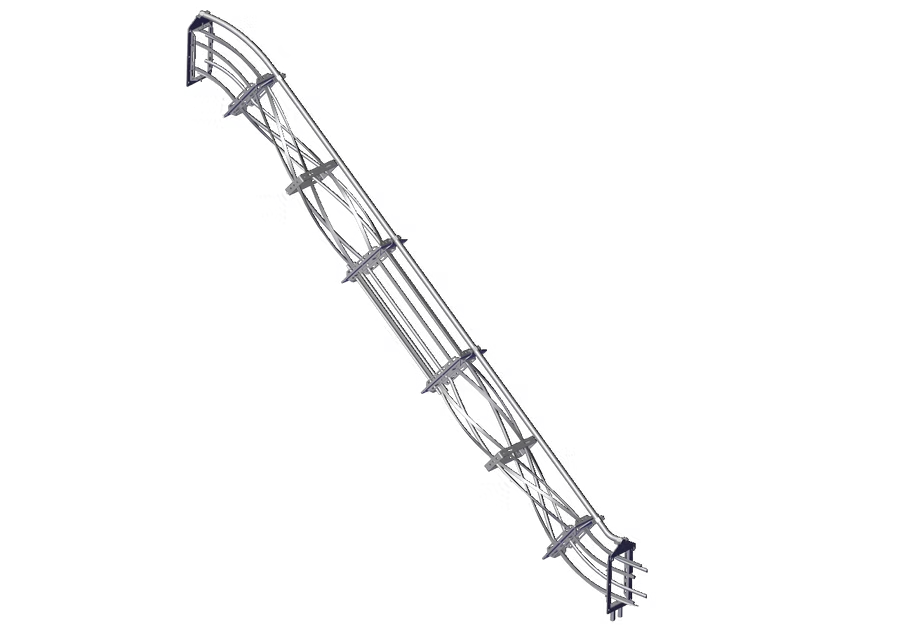

Design touches that improve day-to-day operations

Robust layouts matter. A thoughtful arrangement minimises walk time between equipment and keeps filters, drains, and wash manifolds within easy reach. When a facility sticks to compact footprints, it reduces conveyor spans and energy waste. The best systems feature self‑draining manifolds, cleanable conveyors, and splash guards that survive month after month of high‑volume use. Maintenance routines stay straightforward, with service ports placed for quick access rather than clever geometry. End users notice the difference in morale and speed—workers spend less time hunting for tools and more time focused on the task at hand.

Maintaining sterility without slowing production

Sterility is less about a single clean bottle and more about consistent, repeatable cycles. Effective cleaning machinery uses validated CIP routines, programmable cycle times, and real‑time monitoring of rinse quality. A reliable system will alert operators to any deviation, be it pressure drops or filter clogging, while preserving product integrity. The design leans on hygienic materials, minimal dead zones, and smooth welds that resist corrosion. In practical terms, a plant gains peace of mind knowing that the same machine can handle different can sizes on alternate runs without a full reconfiguration, keeping audit trails neat and traceable.

Scalability that keeps pace with demand

As orders grow, the true test is whether the line can expand without tearing down more than necessary. Scalable packaging gear grows with the brand, not away from it. Look for modular feeders, expandable capping stations, and swappable coating modules that enable a broader product mix. A well‑engineered system can shift from a 24‑hour to a high‑capacity cycle without mid‑night alarms or rushed retrofits. This level of flexibility protects margins, allowing teams to respond to seasonal spikes and market shifts with calm and clarity, rather than last‑minute pressure and costly downtime.

Conclusion

When a production floor embraces industrial can cleaning machinery that ticks every box—efficient, quiet, easy to service—the whole line breathes easier. Cleanliness becomes a byproduct of thoughtful design, not a bystander who arrives late to the shift. Operators report fewer jams, quicker changeovers, and a more predictable exit for every can that leaves the washer. The same discipline translates to packaging, where turnkey packaging line solutions provide a unified, fast, and repeatable path from empty to finished goods. In plants where sanitation and speed are non‑negotiable, the right machinery creates momentum, lowers risk, and frees teams to focus on quality rather than chasing problems all day long.